To Grit or no Grit?

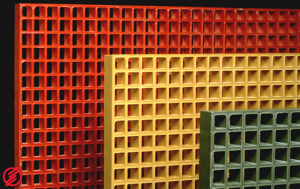

The three questions we are most often asked when a customer is considering part of our line of fiberglass reinforced polymer (FRP) are…

1.) “I need it corrosion resistant” (answer: all of our resins have at least ‘good’ corrosion-resistance)

2.) “I need a UV inhibitor” (answer: all of our resins use a UV inhibitor system)

3.) “I need an anti-slip surface” – this is a little complicated…

Similar to the other answers above, the short answer would be all of our grating is anti-slip. But the grating systems differ whether or not it is pultruded or molded. The pultruded system is easiest to answer. Ordering without a grit system is possible, on request, but most stocked material will have grit embedded in the surface.

Similar to the other answers above, the short answer would be all of our grating is anti-slip. But the grating systems differ whether or not it is pultruded or molded. The pultruded system is easiest to answer. Ordering without a grit system is possible, on request, but most stocked material will have grit embedded in the surface.

Molded grating is a little more complicated. The molding system involves glass rovings and resin layered in an open-faced mold. When the grating is cured a miniscus forms at the top of the grating’s surface. This concave surface forms naturally and provides a measure of anti-skid protection. If grit is desired, there are two types of grit that can be applied:

Secondary grit (“Add-on”): this gritting system involves an epoxy being added on to the surface of the grating and coarse quartz added on the surface followed by a top-coating of pigmented sealing epoxy added to seal the grit. This has the benefit of economy and can be applied on any standard sizes of grating kept in inventory.

Integral grit: A more complex system, this premium grit must be spec’d in along with the initial material order – it cannot be added after the grating cures and therefore cannot be added on to materials kept in inventory. The benefit is the grit is part of the structure of the grating, it is less likely to chip and more likely to retain the optimal non-slip surface. This system will require a longer lead time than secondary gritting.

If you have other questions on gritting, grating, or our other FRP products, please contact us.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684