Grating

Image property of Strongwell

DURADEK® Standard Pultruded Grating

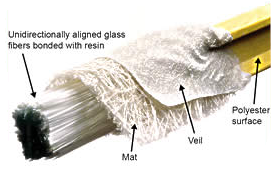

DURADEK® is a standard pultruded grating product stocked by distributors nationwide. It is available with individual bearing bars in either 1″ or 1-1/2″ “I” shapes or a 2″ “T” shape. DURADEK® is a flame retardant product utilizing a polyester or vinyl ester resin. The bearing bars use both longitudinal (glass roving) and multidirectional (glass mat) reinforcements as well as a synthetic surfacing veil to provide unequaled corrosion resistance.

DURAGRID® Custom Grating

DURAGRID® custom grid and grating systems are designed to accommodate specific applications that cannot effectively be met by a standard fiberglass grating. DURAGRID® offers the customer options such as selection of bar spacing (which creates varying open space in the grating or grid), bar shape, cross-rod placement, custom fabrication, custom resin or color.

Image property of Strongwell

DURAGRID® Heavy Duty Grating

DURAGRID® Heavy Duty Grating is a pultruded bar type grating that can be designed and used like traditional metal grates. The solid individual bearing bars are designed to take heavy wheel traffic such as fork lifts, tow motors and truck traffic. Heavy duty grating is constructed of the same type composite used in the other DURAGRID® products.

Image property of Strongwell

DURAGRID® Phenolic Grating

DURAGRID® Phenolic grating is a dramatic innovation for markets where fire safety is a major concern; it offers superior resistance to flame and high temperature with low emissions of smoke and toxic fumes. The nonflammable nature of phenolics enable phenolic grating to withstand higher temperatures than polyester or vinyl ester for extended periods of time without major structural damage. Combined with low thermal conductivity, this provides fire protection not available with alternate materials. DURAGRID® Phenolic grating was the first composite grating to receive U.S. Coast Guard approval. It is accepted for use in locations and applications as allowed in the U.S.C.G. Policy File Memorandum 2-98 for fire retardant grating meeting structural fire integrity Level 2(L2).

Features of DURADEK® & DURAGRID®

-

Image property of Strongwell

Extremely Strong

- Corrosion Resistant

- Impact Resistant

- Low Electrical and Thermal Conductivity

- Non-skid Surface

- Easily Fabricated in the Field

Many features of pultruded grating that are critical to industrial applications have been compared on a point-for-point basis to molded fiberglass, aluminum and steel gratings.

Designing with Pultruded Fiberglass Grating

Complete load tables and properties can be requested by contacting Redwood Plastics. The bearing bars are assembled into 12 panel sizes for your convenience; 3-, 4- and 5-foot widths in each of 8-, 10-, 12- and 20-foot lengths. Standard panels come with cross-rod spacings of 6″ or optional 12″ on center.

Surface Texture

Grids can be ordered with or without an anti-skid grit surface. A variety of grit material and textures can be ordered.

3-Piece Cross-Rod System

The 3-piece cross-rod system is the best assembly method for pultruded grating in the fiberglass grating industry because it provides better stability than competitive crossrod systems. The three piece members in combination with a proprietary bonding method tie the bearing bars together and provide stability to the grating panel.

Grating Meets Virginia Graeme Baker Act UV Requirements

DURADEK® and DURAGRID® pultruded fiberglass grating, including I-4000 and T-1800 which are typically used in the pool and spa market, have been tested and meet UV requirements mandated by the Virginia Graeme Baker Act (VGBA). The grating is the ideal solution for fabricating VGBA compliant drain systems.

Stork Materials Technology, an independent testing facility, tested our pultruded grating for tensile strength and impact strength after being subjected to ultraviolet (UV) radiation weathering. The independent testing was performed in accordance with ASTM D638 for tensile testing and ASTM D256 for Izod impact testing.

The testing results indicate DURAGRID® grating has a K factor of 1.02 for AMSE A112.19.8.a – 2008, section 3.2.2.3, which is the testing protocol for grates and grating covering pool drains.

Redwood’s grating has been successfully used to fabricate field or replacement drain systems for years because the benefits of DURADEK® and DURAGRID®:

Strength — DURADEK® and DURAGRID® are extremely strong and impact resistant

Low Maintenance — Corrosion resistant fiberglass with molded-in color will outlast aluminum or steel grating with virtually no maintenance, even when submerged under water.

Cost Effective — Redwood’s pultruded grating is lightweight and, therefore, easily handled in installation, and cost less to ship than steel grating.

Safety — DURAGRID® grating is low in electrical and thermal conductivity and can have a non-skid grit surface.

Strongwell’s VGBA (Virginia Graeme Baker Act) UV compliant grating can be found in the construction of certified anti-entrapment grates as well as field fabricated drains.

NOTE: Fiberglass grating has been used in chlorinated, brominated, and salt water applications as well as many harsh outdoor exposure applications for many years. It has also been used (and is currently being used) in subsea applications. We are not aware of any product failures due to such water or ultraviolet radiation exposure for periods exceeding 20 years. If pool and spa fiberglass drains are properly maintained and not subjected to any abnormal use or damage, we therefore believe, but cannot guarantee, that the FRP grating should have a life expectancy of at least 20 years and likely much longer.

Image property of Strongwell

Fabrication

DURADEK® and DURAGRID® gratings are lightweight and, therefore, easily handled in installation, and cost less to ship than steel grating. A patented 3-piece cross-rod system mechanically locks and chemically bonds the cross-rods to the web of each bearing bar. This separates and affixes bearing bars firmly in position and distributes concentrated loads to adjacent bars. The system allows DURADEK® and DURAGRID® grating to be cut and fabricated like a solid sheet.

Standard carpenter’s tools with abrasive cutting edges may be used; just coat the cut ends with resin sealer and install. A detailed Field Fabrication Guide is available by contacting Redwood Plastics.

Attachment Methods

A Decking Fasteners flyer is available that provides information on the preferred fasteners available for all decking products. Illustrations of the various fasteners and uses are exhibited on the back of the flyer.