Molded or Pultruded Grating?

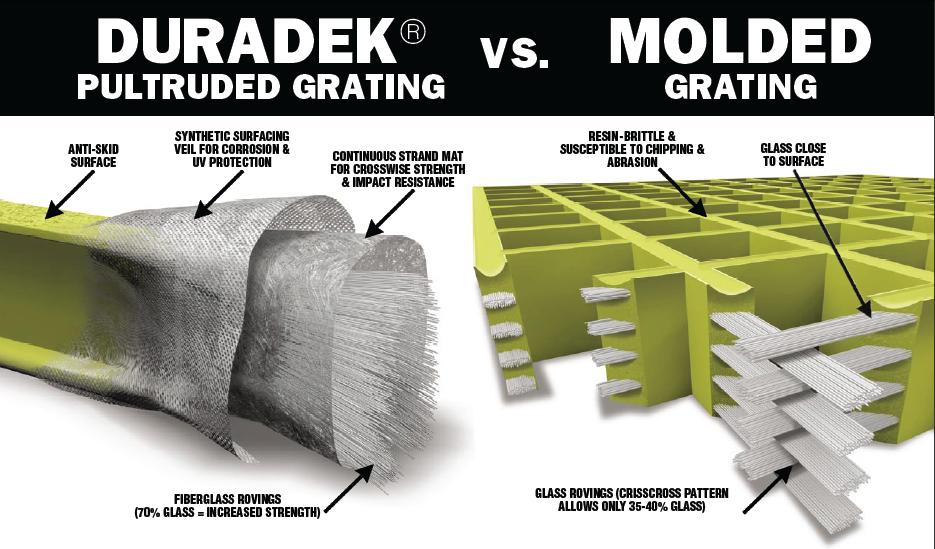

We carry two types of Fiberglass Reinforced Polymer (FRP) grating – molded and pultruded – and we are often asked about the differences between the two. Molded grating ,Redco™ DURAGRATE®, is easier to produce and costs less. Molded grating provides a corrosion resistant, non-conductive material that costs less than pultruded grating. However, there are disadvantages to the material that one must consider:

-Limited profile shapes

-Air bubbles in the molding process cause exposure to chemical attack

-More difficult to cut and fabricate with

-Higher resin content results in a more brittle material

Pultruded grating, our Redco™ DURADEK®, is a superior grating material offering significant advantages over molded grating. It can be customized to fit a wide-range of profiles and the pultrusion process results in a consistent material with glass fibers suppressed by a surfacing veil that provides uniform protection. The silica-grit surface provides excellent anti-slip properties and its added glass content results in a stronger composite. This illustration shows a quick comparison of the material.

We strongly believe in the properties of both our Redco™ DURAGRATE® and our Redco™ DURADEK® but, if possible, pultruded grating is a better choice in most applications. We understand many factors affect the purchase decision so we ask you to contact us to help discover which choice is appropriate for your application.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684