When is Fiberglass the Better Choice?

Trying to decide what materials to use for a new structural development project? There are a number of materials to consider when engineering and designing a new structure, and Fiberglass Reinforced Polymers could be the right choice. These materials have outstanding properties that are better suited for a variety of environments.

FRP, or Fiberglass Reinforced Polymers, certainly aren’t new to the marketplace. FRP’s have been around for many years, but it has taken some time for them to become universally accepted around the world, by Engineers, architects, and developers. FRP’s, for commercial use, have been extensively researched since the 1930’s, however, Engineers, architects, and developers, being unfamiliar with the material and uncertain as to which grade of FRP is the correct one, sometimes overlook FRP as a structural material.

Understanding FRP plastics and where they are best suited is important, and comes from an understanding of the products strengths and weaknesses. There are many grades of FRP’s and not all of them can be used for the same application. Although all fiberglass products are not created equal, FRP products generally share these characteristics:

- Lightweight – Weighs 80% less than Steel

- Corrosion Resistant

- Low Conductivity – Thermally & Electrically

- Nonmagnetic – Electromagnetic Transparency

- High Strength

- Dimensional Stable

- Low Maintenance

The end result: Fiberglass Reinforced Polymers becomes an excellent substitution for steel, aluminum, concrete or wood. In cases where the use of traditional products comes into question, such as situations where there may be rotting or corrosion, FRP products are often a much more sound choice. These FRP products typically last longer, are easier to maintain, and improve safety.

Significant cost savings are also a key benefactor when choosing FRP products. Not only because they have significant longevity and are virtually maintenance free, but also because the materials are lighter. The reduced weight decreases shipping costs and makes installation easier, which saves time during the construction phase. As an example, in a wastewater treatment facility, FRP was used as an alternative to galvanized steel for handrails, ladders, and walkways; the installation was 50% faster due to the lightweight materials and ease of assembly.

Although they have many uses and applications, REDCO™ Fiberglass Reinforced Polymer products are typically available in three major product types; structural shapes, grating, and wall paneling.

Structural Shapes

Structural Shapes

Structural shapes (REDCO™ EXTREN®) are produced in hundreds of shapes and are a strong, lightweight option for platforms, walkways, structures, floors, ladders, panels, decking, enclosures, handrails, and covers.

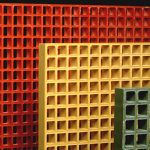

Grating

Grating

Grating is available in both molded (REDCO™ DURAGRATE) and pultruded form (REDCO™ DURADEK® & REDCO™ DURAGRID®), and is best suited for higher traffic applications, like walkways, docks, drainage grates, and platforms.

Wall Panels

FRP wall panels are suitable for less demanding applications, like commercial kitchens and washrooms but can also be used for impact resistance applications, such as storm panels and ballistics resistance panels.

Applications have been provided to a variety of industries including:

- Architectural

- Tool Manufacturing

- Dairy and Food Processing

- Oil & Gas

- Water/Wastewater Treatment

- Electrical Substations

- Waterparks

- Marine & Fisheries

- Chemical Processing

- Hotels & Restaurants

- Power Plants

- Pulp and Paper

- Material Handling

- Hospitals

When choosing the correct grade of fiberglass, there are some factors to consider and understand. These factors include chemicals that may be present in the environment and load bearing capacity. Fire resistance concerns must also be evaluated, as not all grades have the same level of fire retardant additives.

Load bearing charts, tolerances, and properties tables are available from Redwood Plastics, and can help you make the best decision when choosing FRP products. Knowing exactly how each grade of FRP withstands use, and how they are made, is key. Also ensure that you are referencing the same brand in the charts that you are using in the application, as the properties will differ from one supplier to the next.

In Conclusion

Fiberglass Reinforced Polymer products are often the best choice, and should not be overlooked as a material to construct with, especially in structural, architectural, and design projects. REDCO™ FRP’s are a great solution when other materials are either ill-suited mechanically or economically. There are a few factors to consider when selecting, ordering, and installing FRP products, but Redwood Plastics has experience and knowledge to help for any given application. Contact us today.