From DEK to GRID

Redco FRP (fiberglass reinforced plastic) pultruded grating is sold under two different names: DURADEK® and DURAGRID®. It’s not uncommon for our customers to ask – what is the difference between the two?

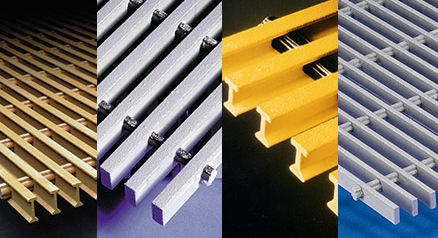

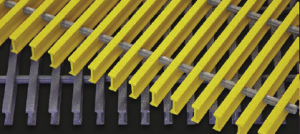

Before we answer that we need to give a quick primer on pultruded grating. The grating consists of the larger bearing bars locked in place by a proprietary cross-rod system. The bearing bars come in three profiles: rectangular, “I” and “T” profiles. The manufacturer pultruded this grating system with space between bearing bar spacing from 0-95%. Furthermore, the panels can be produced in 3′,4′, and 5′ widths and lengths of 8′, 10′, 12′ and 20′ lengths. This is not to mention the multiple resin systems available.

resin systems available.

As you can see, there are a large number of potential premutations for the panels between the differing lengths, widths, bar spacings and resins. To stock and record all of these would be impossible.

Instead, DURADEK® represents a collection of the most common pultruded grating profiles requested. These are stocked at Strongwell with readily available load tables for engineers. Therefore DURADEK® is known as Redco FRP’s “Standard Pultruded Grating.” A few grades of DURADEK® even compare in cost to molded grating. Offering a premium solution without the cost.

DURAGRID® is any grating which is custom pultruded for the customer. These are non-stock profiles and may be subject to a longer lead time and minimum order. However, DURAGRID® can solve problems in certain applications that DURADEK® cannot.

If in doubt, contact us for assistance with your application.