News

Pultrusion Outperforming Molded Grating

“You get what you pay for”

A phrase of wisdom so widely used it is a cliche but it never hurts now and then to have a reminder of how true that statement is.

Recently Redwood Plastics was approached by a large, well-known client in the food processing industry. For years the plant had been using molded grating as it is corrosion-resistant. However, after just a few years of use the grating would start to “droop.” The company wanted to replace the grating with more of the same, which they had purchased from us years ago. Instead, we suggested that they considered our new pultrusion grating. The pultruded grating was not only lighter, but much stronger. To be honest, it was a bit of a difficult sell – the upfront cost of pultruded grating, a premium solution, can seem intimidating and it cost almost three times as much as the common molded grating.

plant had been using molded grating as it is corrosion-resistant. However, after just a few years of use the grating would start to “droop.” The company wanted to replace the grating with more of the same, which they had purchased from us years ago. Instead, we suggested that they considered our new pultrusion grating. The pultruded grating was not only lighter, but much stronger. To be honest, it was a bit of a difficult sell – the upfront cost of pultruded grating, a premium solution, can seem intimidating and it cost almost three times as much as the common molded grating.

However, the company trusted our advice and went with pultrusion. They were extremely happy with the final product – it’s strength and advantages were easy to see. Furthermore, as a customized solution, the grating fit better into the trench and eliminated the problem of a “lip” that the plant was having with their old grating.

The increased strength of pultruded grating means it will not bend and need to be replaced in a few years unlike the molded grating and is virtually maintenance free. Therefore the life cycle cost of the material will be much less than molded grating, which only appears to be cheaper.

As our client quickly learned – you really do get what you pay for.

If you would like to know more about pultruded FRP grating or other solutions please contact us today:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

FRP: What Is Price, Really?

It is one thing to promote a product’s advantages and benefits, it is another to discuss one issue no one is comfortable discussing unless they are sure it is in their favor: price.

It is one thing to promote a product’s advantages and benefits, it is another to discuss one issue no one is comfortable discussing unless they are sure it is in their favor: price.

Redco™ FRP materials offer numerous advantages and benefits over traditional materials: steel, aluminum and wood. That said, upfront costs with FRP materials are often significantly higher than traditional materials. That is the truth of the material.

However, that does not tell the whole story. The life cycle cost of FRP materials are often much less than traditional materials. Regarding the life cycle costs, the following questions need to be asked of traditional materials:

Will significant time be spent on maintenance over the life cycle (cleaning, repainting, resurfacing, protecting)?

-Might the traditional materials need replacement due to corrosion, rust or rot?

-Is safety an issue due to possible degradation of traditional materials?

-Are there electrical hazards?

-Is ease of installation important?

Those are just a few examples of questions you need to consider before choosing traditional materials for your application. If you are unsure about how steel, aluminum or wood will hold up in answer to any of the questions above, there is a good reason to consider FRP. If you are unsure of traditional materials in your application regarding to any two of those questions or more then FRP likely is an excellent alternative.

For answers to your questions on FRP materials please contact us.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

Pultrusion Power

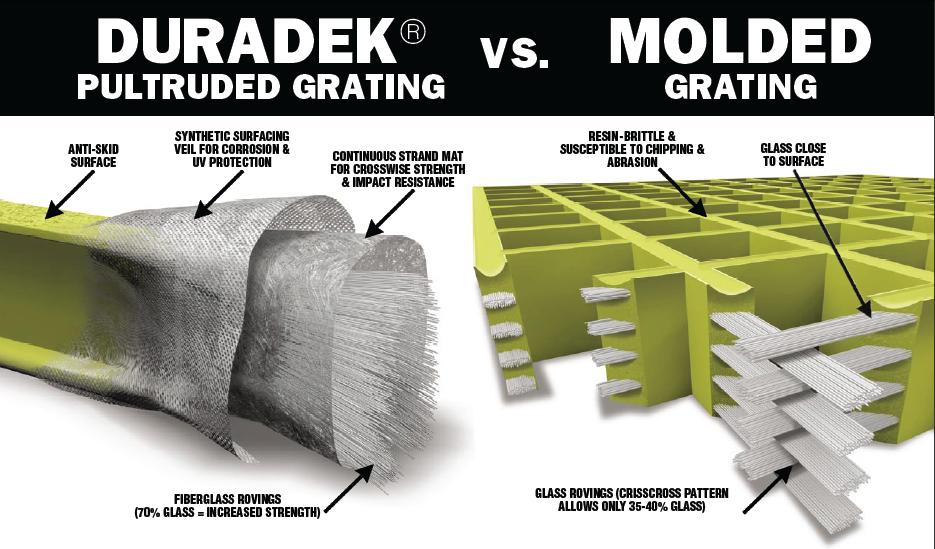

While Redco™ does carry some “traditional” molded FRP products, our pultruded FRP products make up the bulk of our product line. Pultrusion offers some significant advantages when it comes to FRP. The strand mat and rovings are always equally distributed due to the pultrusion process, providing a consistency that molded grating cannot match. Furthermore, pultrusion covers the FRP product in a synthetic surfacing veil. This veil provides two benefits: 1.) it keeps the glass rovings from the surface and 2.) provides UV protection.

The process itself is very interesting. Rovings and strand mat are drawn from large drums and pulled together via a system of guide plates. The glass materials are then saturated in a resin impregnator where the surfacing veil is applied immediately after saturation. Next a system of reciprocating pullers draw the material from a forming & curing die to a cut off saw at the end of the machine. The advantage of this process is that a wide range of lengths are available to the customer.

Words do not do the system justice. Take a look at this short video that shows the process using 3D graphics:

For more information on our exciting line of FRP materials contact us today.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

Molded or Pultruded Grating?

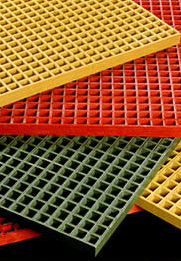

We carry two types of Fiberglass Reinforced Polymer (FRP) grating – molded and pultruded – and we are often asked about the differences between the two. Molded grating ,Redco™ DURAGRATE®, is easier to produce and costs less. Molded grating provides a corrosion resistant, non-conductive material that costs less than pultruded grating. However, there are disadvantages to the material that one must consider:

-Limited profile shapes

-Air bubbles in the molding process cause exposure to chemical attack

-More difficult to cut and fabricate with

-Higher resin content results in a more brittle material

Pultruded grating, our Redco™ DURADEK®, is a superior grating material offering significant advantages over molded grating. It can be customized to fit a wide-range of profiles and the pultrusion process results in a consistent material with glass fibers suppressed by a surfacing veil that provides uniform protection. The silica-grit surface provides excellent anti-slip properties and its added glass content results in a stronger composite. This illustration shows a quick comparison of the material.

We strongly believe in the properties of both our Redco™ DURAGRATE® and our Redco™ DURADEK® but, if possible, pultruded grating is a better choice in most applications. We understand many factors affect the purchase decision so we ask you to contact us to help discover which choice is appropriate for your application.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

Waste Processing Solutions

Redco Fiberglass Reinforced Plastic (FRP) materials have numerous advantages over traditional materials. First and foremost is the ability to resist corrosion. This corrosion could be due to outdoor elements such as poor weather and salt but our materials also resist chemical corrosion. This makes the material especially valuable in waste water and waste processing applications.

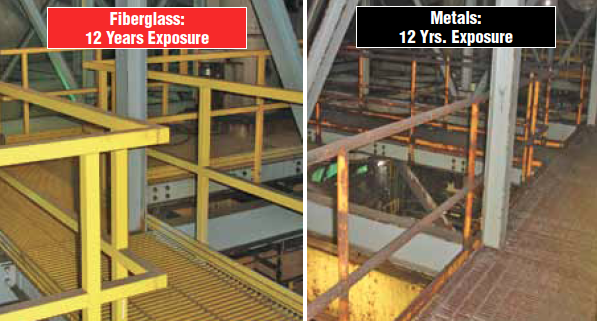

Not only will our FRP outlast wood and steel, but it is virtually maintenance free. The material will not require repainting and is easily cleaned. Take a look at this comparison of both materials after 12 years use:

The FRP materials hold up very well while the steel shows clear signs of corrosion. The safety concerns and potential replacement costs (with accompanying facility downtime) make FRP materials a sensible choice. The picture segways into another benefit of the FRP materials – versatility. Not only do we provide pultruded and molded grating, but we have the accompanying railings, ladder and stairway systems. This provides a “360 degree” FRP solution to your application ensuring that your employees are safe and your maintenance is kept to a minium.

For assistance or questions about your application please contact us.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

STRONGRAIL Architectural Solutions

Many RedcoFRP products seem to be focused on heavy industry but we provide some attractive products for consumers as well. Redco™ STRONGRAIL® is one such solution, as it was designed to provide a maintenance free alternative to traditional building materials.

Think of the ritual each spring of painting and repairing the various fencing and railings around one’s home or condominium. Redco™ STRONGRAIL® is weatherproof, does not require repainting and is much stronger than wood and will not rot. The material is just as aesthetically pleasing as fencing and railing made from tradition materials, yet has a lower life cycle cost. In a high-density development such as apartments or condominiums the maintenance time saved can offer significant benefits to the tenants.

and will not rot. The material is just as aesthetically pleasing as fencing and railing made from tradition materials, yet has a lower life cycle cost. In a high-density development such as apartments or condominiums the maintenance time saved can offer significant benefits to the tenants.

These benefits are especially apparent in corrosive environments such as oceanfront properties or waterparks. The product can be made to meet ADA requirements and comes in a variety of standard systems; however, custom systems are available on request.

Redco™ STRONGRAIL® is an attractive architectural solution for a variety of applications. For more information please contact us.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

STRONGRAIL® is a registered trademarks of the Strongwell Corporation

How DURADEK® and DURAGRID® Pultruded Grating is Made

Redwood Plastics proudly distributes fiberglass pultruted grating; DURADECK and DURAGRID, which is manufactured by Strongwell.

Strongwell’s 3-piece cross-rod system is the best assembly method for pultruded grating in the fiberglass grating industry because it provides better stability than competitive crossrod systems. The three piece members in combination with Strongwell’s proprietary bonding method tie the bearing bars together and provide stability to the grating panel. This system makes Strongwell’s pultruded grating the superior choice in the marketplace. Watch the video below to see how it’s done.

For more information visit our page on these two products.

Redco Introduces New FRP Product Lines

Recently Redwood Plastics Corporation and Strongwell, the world’s largest producer of pultruded materials, signed a distributorship agreement. This has greatly expanded Redwood’s Fiberglass Reinforced Plastic (FRP) product lineup. The pultrusion process allows for materials to be produced in almost unlimited lengths, limited only by the application and freight restrictions. With the number of new products available we wanted to draw attention to a few highlights.

Redco™ SAFRAIL™ fiberglass handrails is a pultruded product suitable for a wide variety of industrial applications. SAFRAIL™ meets OSHA strength requirements and provides a 2:1 safety ratio. Redco™ SAFRAIL™ is particularly well suited to corrosive environments where liquid or airborne corrosive agents, such as salt, may be present.

The product outlasts other metals including aluminum and is non-conductive and maintenance free. SAFRAIL™ is easy to install with its internally bonded fiberglass connectors meaning no visible rivets or metal parts.

Redco™ DURADEK® is a standard pultruded grating system that offers numerous advantages over traditional metal materials. Like other FRP materials, Redco™ DURADEK® is corrosion-resistant, non-conductive, and maintenance free. The product is flame-retardant and securely bonded with a proprietary method utilizing a 3-piece cross-rod system.

Redco™ DURADEK® has been successfully used in various industrial applications, notably in marine and waste treatment. The grating is available in both polyester and vinyl ester resins and includes a synthetic surfacing veil for increased UV and corrosion resistance.

Redco™ EXTREN® is a series of fiberglass reinforced building shapes and structures available in over 100 standard dimensions. Its properties include high strength, lightweight, corrosion resistance, low thermal and electrical conductivity and electromagnetic transparency.

That electromagnetic transparency property of Redco™ EXTREN® makes the material especially suited for applications such as cell phone towers or buildings involved in the scientific testing of systems like radar.

Redco™ EXTREN® is available in three grades: Series 500 (polyester resin with UV resistance), Series 525 (polyester resin with increased flame-retardant properties) and the Series 625 (Vinyl Ester resin with premium fire retardant and corrosion resistance properties).

For more information on Redwood’s exciting new line of FRP materials check out:http://www.redwoodplastics.com/products/frp-fiberglass-reinforced-plastics/ or contact us today.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

EXTREN®, DURADEK® and SAFRAIL™ are registered trademarks of the Strongwell Corporation.