News

Beauty, Architecture & FRP

FRP (fiberglass reinforced plastic) is well-regarded in industrial circles; however, few people consider the benefits of FRP outside of the mill, the mine or the marina. One such place is in architecture, where FRP pultrusions not only outlast traditional metal and wood – but do it looking just as good, if not better! Examples of applications include: marina platforms, pseudo-metal decorative, screening, decorative fencing, architectural columns and more. Our manufacturer, Strongwell, has produced an excellent video less than 10 minutes long which illustrates many of these examples. Take a look:

Contact us for more information.

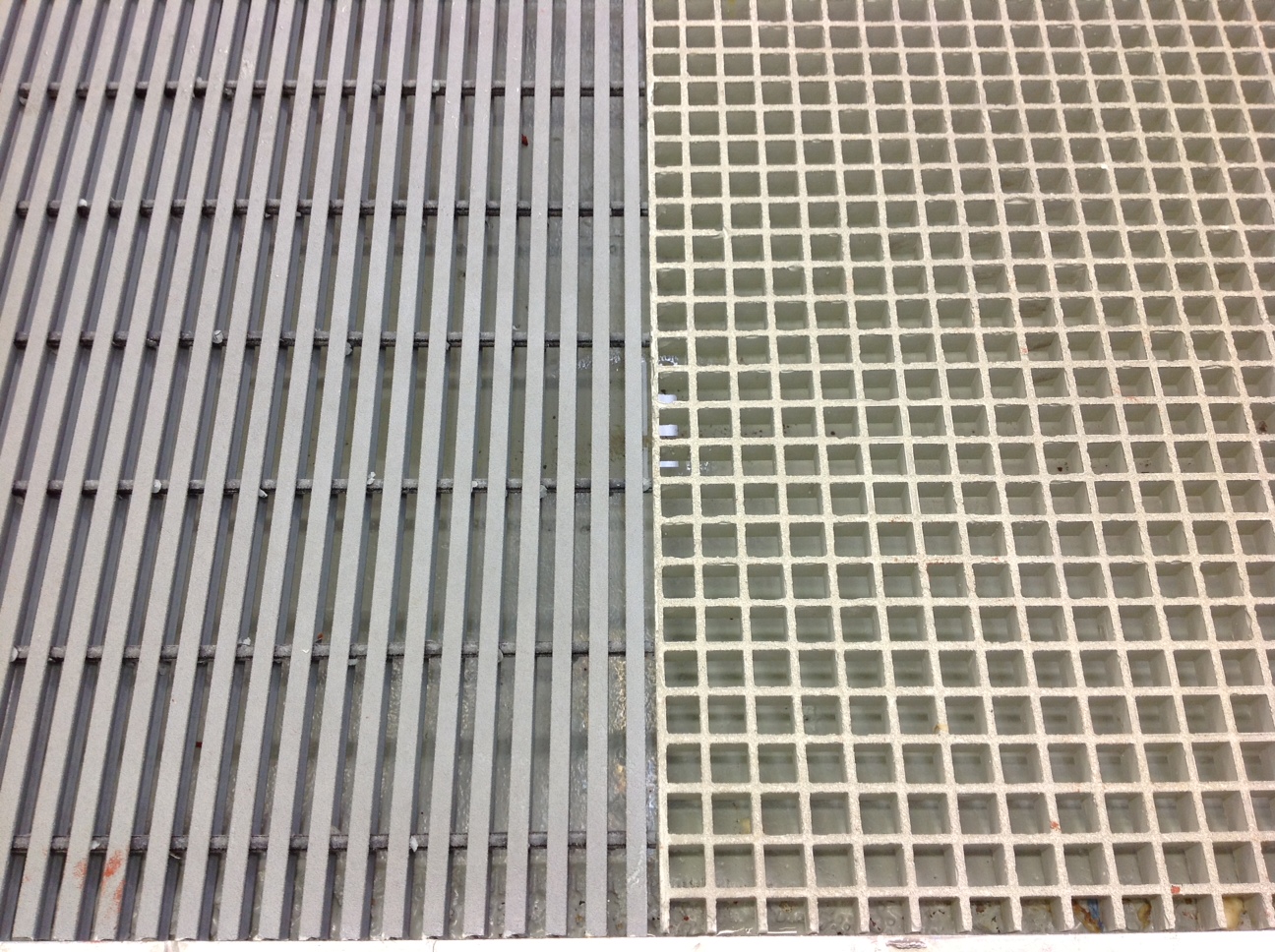

I-6500: Pultrusion vs. Molded

Pultruded fiberglass reinforced plastic (FRP) grating is superior to the more commonly specified molded grating in almost every way. It is stronger, has less deflection and is more customizable. The drawback is price – with one exception – I-6500 pultruded grating. The I-6500 was designed to help overcome price objections vs. pultruded grating. This mass produced profile has, as you might expect, an “I” bearing bar profile with 65% space in between the bearing bars and a standard 1-1/2″ thickness.

The price is roughly equivolent to molded grating and actually costs less if purchased in quantity. I-6500 is well stocked in three locations across the U.S. making it accessible to customers wherever they might be. It performs very well in a variety of foot traffic applications and can be seen as a “general purpose” grating. Vehicle traffic is not recommended on the I-6500.

For a comparison of I-6500 to molded grating click here.

From DEK to GRID

Redco FRP (fiberglass reinforced plastic) pultruded grating is sold under two different names: DURADEK® and DURAGRID®. It’s not uncommon for our customers to ask – what is the difference between the two?

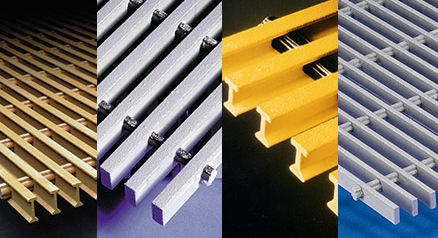

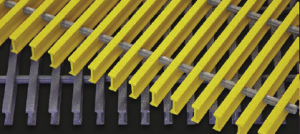

Before we answer that we need to give a quick primer on pultruded grating. The grating consists of the larger bearing bars locked in place by a proprietary cross-rod system. The bearing bars come in three profiles: rectangular, “I” and “T” profiles. The manufacturer pultruded this grating system with space between bearing bar spacing from 0-95%. Furthermore, the panels can be produced in 3′,4′, and 5′ widths and lengths of 8′, 10′, 12′ and 20′ lengths. This is not to mention the multiple resin systems available.

resin systems available.

As you can see, there are a large number of potential premutations for the panels between the differing lengths, widths, bar spacings and resins. To stock and record all of these would be impossible.

Instead, DURADEK® represents a collection of the most common pultruded grating profiles requested. These are stocked at Strongwell with readily available load tables for engineers. Therefore DURADEK® is known as Redco FRP’s “Standard Pultruded Grating.” A few grades of DURADEK® even compare in cost to molded grating. Offering a premium solution without the cost.

DURAGRID® is any grating which is custom pultruded for the customer. These are non-stock profiles and may be subject to a longer lead time and minimum order. However, DURAGRID® can solve problems in certain applications that DURADEK® cannot.

If in doubt, contact us for assistance with your application.

Custom Fabrication & Design

The breadth of the Redco FRP (fiberglass reinforced plastic) line can seem overwhelming at times with the sheer amount of products available. These products can be purchased with multiple resin systems, additives and profiles as well. A representative can help you select the right product for your application.

But then what?

The reality is, not every customer is a fabricator who knows how to work with FRP. In fact, many customers do not have engineered plans – just an idea of what they would like to accomplish. Fortunately, Redco FRP through our manufacturer, Strongwell, has access to both engineers and extensive “in-house” fabrication. What is required though is more than a simple “I want to build a ____” statement – the customer will be required to provide specific details, and figures, about the application environment such as UV-exposure, temperature range, chemicals, fire risk, and loads. Engineers that design these structures are personally responsible for their designs. We simply cannot design and fabricate a solution if we do not have all of the required information!

While we have access to engineers who have their stamp for many states, we can also provide a stamp from an engineer in whichever state is required, for an additional premium. On the fabrication end, we can cut, drill, paint and even partially assemble projects before transportation to the end-user, such as this Strongwell FRP bridge in Barbados which was custom fabricated in four sections.

(Pultruded FRP bridge in Barbados)

Creatively Composolite

The classic 1980’s TV character “MacGuyver” was notable for his innovative use of tools and materials to solve problems in ways you would not expect. While the problems solved may be less dramatic, FRP can be used in similarly innovative applications. For example, FRP grating – originally designed for flooring – has been used extensively as a visual screen. Redco™ COMPOSOLITE® can be used creatively as well. Originally designed as a structural building material, COMPOSOLITE® building panels have been used in bridges, cooling towers and even restaurants. One application that has proven valuable is as tank covers at wastewater treatment plants.

Traditionally these are made of aluminum; however, aluminum (typically) does not have the strength to handle foot traffic. FRP is not only lighter than aluminum but is strong enough to handle that foot traffic. They are also hollow so accessories such as handles can be placed inside the panel. Redco™ COMPOSOLITE® is corrosion-resistant, low in thermal and electrical conductivity and easy to install. For more information, contact us.

Choosing Your Resin

When ordering Redco™ FRP products, such as grating, it is not as simple as saying how many sheets of what size and color grating. Resin selection is important and there are a surprising number of choices available. You should carefully consider your application before making a decision as the choice may have a dramatic impact on the grating lifespan. The choices are as follows:

- VE-a premium grade vinyl ester, for high chemical resistance

- NVE-a premium grade vinyl ester, for high chemical resistance and is NSF-61 certified for hot and cold potable water

- XVE-a premium grade vinyl ester, with extra fire resistance (a flame spread rating of 10 or less)

- PP-an all-purpose isophthalic polyester for industrial applications

- NPP-an all-purpose isophthalic polyester for industrial applications and is NSF-61 certified for hot and cold potable water

- GP-a general purpose orthophthalic polyester for architectural or other applications with less corrosion problems

- FF-an economical isophthalic polyester for food processing or similar applications

As you can see, some of the choices overlap. For example, there are two NSF-61 certified choices for applications in or around potable water. Therefor other criteria, such as the level of chemical resistance required, need to be considered in order to make the correct selection. Need help? A Redco™ FRP rep would be happy to assist you.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

A Flying Rig

One of our largest projects we’ve worked on has been suppling pultruded Redco™ Duragrid grating for a more environmentally friendly rig by Cenovus. The rig is about half the size of a regular rig and is flown in by helicopter to remote areas. This reduces the environmental footprint on the land and does not require a fleet of trucks to drive everything in.

Our pultruded grating was chosen for a number of reasons. It is a superior grating system to molded FRP grating that often specified. Furthermore, despite our grating being more expensive than Asian competition – it was still selected due to the confidance our client had in North American manufacturing and quality control. When it comes to drilling for oil, you have to do it right!

Redco™ Duragrid has been a valued part of these drilling rigs and we have done several, just one application in many where premium pultruded FRP displays its value.

You can see our grating at the 0:46 point of this video:

Cooling Towers – Wood vs. FRP

Since the 1980’s fiberglass reinforced plastic (FRP) has been recognized as the best structural material for cooling towers. Engineers and contractors familiar with Redco™ FRP already know that it will not rot, rust, corrode or permit insect attack. What you might not be aware of is that Redco™ FRP components can replace wood directly – specifically replacing wood in a cooling tower that was designed to use wood. There are a few ways about this. Firstly, in “stick built” towers stock-shape FRP materials can more or less replace wood as-is.

When it comes to other towers, modular, reconstructions or “shop-built” FRP components can be custom pultruded to reduce the amount of components required and to increase the speed of construction. If necessary, Redco™ FRP components can be pultruded to match the exact dimensions of any wood material that may have been specified.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

FRP on The Farm

Recently we have received a few inquiries on Redco™ pultruded and molded grating for farms and ranches. In all cases, our contacts were looking for a floor that would not rot or corrode and be very low-maintenance. A crowded area teeming with livestock is difficult and unpleasant to clean – hopes were that Redco™ FRP (fiberglass reinforced plastic) would provide a stable, long-lasting floor. While FRP does have its uses as flooring for livestock there are important limitations to consider.

Firstly, molded grating is not recommended. Despite the higher resin content, the grating chips more easily by the hooves of the animals. Pultruded grating can work but it depends on the livestock as the shape of the hoof and the gait of the animal is important. T-1800 grating (18% spacing between bearing bars) is a good choice for pigs while T-3000 grating is best for sheep. Unfortunately, due to their hooves and particular gait, no Redco™ FRP grating is suitable for horses or cattle.

If these limitations can be worked around, Redco™ pultruded grating is an excellent choice. The spaces between bearing bars let liquids and other debris fall between the cracks (presumably to an area that is easier to clean out) and the excess food or animal by-products will not have an effect on grating strength, lead to rot, or otherwise a weaken the floor.

The best way to ensure a correct choice of material is to get in touch with a Redco™ FRP representative who will help ensure the correct material is specified for your job.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

From Heavy Industry To Your Home

One problem with the reputation fiberglass reinforced plastic (FRP) has is that it is considered just a solution for heavy industry. This is not true – many of the properties of FRP serve consumer architecture and housing very well: corrosion resistance, very low maintenance and ease of installation. Redco™ FRP has all of those properties and it looks great! Our manufacturer has done substantial design work on attractive residential FRP products that mimic solutions made out of traditional materials.

Past installations have run the gambit from fencing at hotels, to stairway railings for apartment complexes and even hurricane-proof homes. The only reason the public doesn’t encounter the material more often is that it is likely in front of their eyes and they don’t even notice! The products look that close to their traditional counterparts. Still not convinced? Take a look at this short video on FRP architecture solutions by Strongwell:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684