News

Custom FRP Pultrusions

The Redco EXTREN line offers a wide variety of profiles to suit a variety of applications in several industries. But there are times where an existing profile still cannot meet the requirements in this case a custom pultrusion may be the solution. When should you consider a custom pultrusion? When it is clear after consultation that the profiles that exist already will not work and the quantity is significant. Significant would mean a few thousand feet worth of material. The ability to manufacture a custom pultrusion gives you a tremendous amount of choice, we can work with you to determine how much UV-resistance the profiles require or how much corrosion resistance. Even the surface finish can be worked out. We will fill out a form on our end used by manufacturing to detirmine the cost and feasibility of a custom pultrusion.

Besides the obvious information, such as your company name and address, we require the following information:

-Any drawings you may have of the part

-Details on the application (what is it doing?)

-What are the most critical features of the part?

-Chemical exposure? What chemicals and how much?

-Is the part being used outdoors? How much sunlight exposure?

-What color does it need to be?

-Does it require fire-retardancy?

-What is the operating temperature?

-How much quantity for the initial run? is the run a one-time run?

-Do you require a prototype?

-When do you need the product by?

-Does the product require any special tolerances?

-Is the part currently being made out of other material? What material?

-Does the part require special packaging?

There’s a lot of information we require but it’s likely you know the answers to most of them immediately. Supplying us with that information will let us consult with manufacturing much more quickly and get back to you on the project.

For assistance with your FRP project contact us today.

Don’t Slip With DURATREAD

Fiberglass reinforced plastic (FRP) solutions tend to be large. Large panels of sheet or grating and even entire structures can be fabricated from FRP materials. Sometimes simpler, smaller products can fall through the cracks – one of those products is the REDCO™ DURATREAD™ stair tread covers. These are hand-molded fiberglass covers to existing stairways. What they provide is a tough, anti-slip solution where this may be a concern. Concrete or wooden steps in moist or cold areas is of particular concern.

The treads are made of strong fiberglass mat and coated with aluminum oxide grit and then painted. The standard color is dark grey with a safety yellow nosing. REDCO™ DURATREAD™ covers are available in thicknesses of 1/8″ and 1/4″. Standard depths are 8″, 9″, 10″, 11″ and 12″. All stair tread covers are available in 12′ lengths. Other lengths and depths are available upon request. The treads can be affixed mechanically or with an adhesive, depending on the application.

There are many potential areas where these treads can be an effective solution including:

• Amusement/Water Parks

• Hotels/Motels

• Outdoor Stairways

• Outdoor Sports Facilities

• Restaurants

• Food Processing Facilities

• Chemical Processing Plants

• Water/Wastewater Treatment Facilities

For more information on the REDCO™ DURATREAD™ stair tread covers contact Redwood Plastics.

FRP Fountain

Pultruded fiberglass reinforced plastic (FRP) grating makes for an excellent drainage grate in waterparks, swimming pools or, as the picture below shows, fountains. FRP will never rot and will easily resist any chlorine or other chemicals used in water treatment. The fiberglass will last many decades and require zero maintenance except for the occasional repainting. Pultruded FRP grating is easily painted to match any application and will blend in with the other components of your application. Unlike metal grating, FRP will not rust and will not conduct electricity. It is more expensive but the savings due to FRP’s lifecycle cost will more than balance out the upfront cost.

It is true that similar looking plastic grating is available at a cheaper cost, but those plastics will have some disadvantages. Firstly, they will not have the strength that Redco pultruded FRP affords, nor will they have the same level of chemical resistance. When a Redwood Plastic rep knows that the application is for a pool or fountain, he/she will ensure it has a UV-top coat at the very least. A complete UV-inhibitor system is available and cheaper grating may not have this, meaning the grating could quickly discolor in sunlight, start to show signs of UV stress, and eventually weaken the entire structure.

For more information on Redco pultruded FRP grating or our other products contact us today.

FRP – The Delivery Question

One area of concern for fiberglass reinforced plastic (“FRP”) customers is delivery time. Besides a few profiles of grating and EXTREN stock, most FRP products are pultruded or molded as-ordered. In many cases these are custom jobs and to ensure the customer gets what they want, final drawings for approval must be made and signed by the customer. It is only after the drawings are signed that the delivery time comes into effect: essentially when the work order is placed at the factory.

Often delivery times for custom profiles, ladders, etc is around 4 weeks. Large projects or custom parts can run 7-8 weeks (or more) lead time after final drawings are signed. Customers often ask about shipping and how that works? Usually the products are quoted from whichever manufacturing facility quotes the job. Most of our customers are industrial corporations and have their own freight accounts; however, for individual or “private” customers we may be able to help with freight arrangements.

There are some FRP products that are not custom and are regularly stocked at the manufacturing locations. These are primarily molded grating, certain grades of pultruded grating and EXTREN shapes and plate. These orders can ship in 1-2 days after an order is placed. If in doubt, ask your Redwood rep.

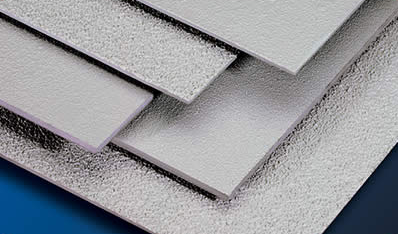

The SAFPLATE Solution

Redco SAFPLATE has been a much requested product in 2015 thus far. We have had inquiries from private customers, to public works, to the military. The reason for this is that SAFPLATE is such an adaptable product that can serve in a variety of applications. The product is fiberglass reinforced plastic (FRP) and comes standard with a fine grit surface on one side. We’ve had customers cut it up for use as stair treads (use Loctite PL Premium Polyurethane Construction Adhesive when bonding to concrete) or just as a general walkway surface. It also serves very well as a trench cover, especially since it resists moisture and chemicals. SAFPLATE is available with a coarse grit surface as a special order.

FRP Handles The Coast

Coastal areas provide a tough environment for materials to survive. Water and salt attack both wood and metal causing corrosion and rot. This results in applications and structures that require a high amount of maintenance and need premature replacement. But there is a better solution: Redco™ fiberglass reinforced plastic (FRP). FRP is not affected by salt, rain or other erosive forces found on the coastline. FRP will maintain its properties while being low maintenance many years after competitive materials need to be replaced. A few applications that have been successful previously:

1.) FRP Mini-mesh or pultruded grating as dock surfacing

FRP works very well as a dock solution as it will not rot or rust and is electrically non-conductive. Applications all over the U.S. and Canada from large scale marinas to small, personal docks have been made using FRP. Often, no hardware is required to affix the material. Customers will often create ‘troughs’ where the FRP can sit in a safe and precise orientation.

2.) Architectural applications

This one might come as a surprise, as FRP is often considered to be an “industrial” product only, but there are many FRP products that are made to look attractive in architectural applications. Strongwell, manufacturers of Redco FRP, once supplied material for a hurricane-resistant home on the Carolina coast. Stairs, fencing and decking are all available in attractive FRP options that resist all types of weathering.

These are just a couple quick examples of how FRP makes an excellent choice for coastal applications. For help with your application, contact Redwood Plastics.

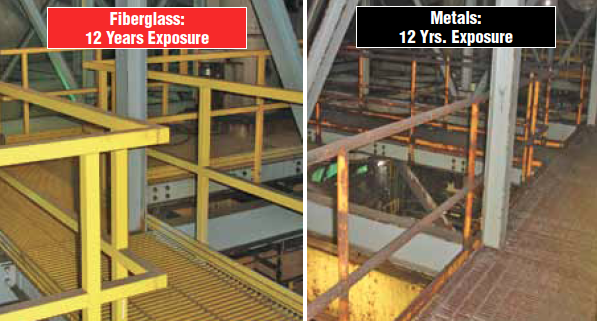

FRP vs. Traditional Materials: Key Properties

Fiberglass reinforced plastic (FRP) is an excellent substitute for traditional building materials (steel, wood, aluminum) in hundreds if not thousands of applications. However, when considering FRP for an application a comparison needs to be made between properties, not price. FRP will often be significantly more expensive, in upfront cost, but offer a lower life-cycle cost and important benefits versus traditional materials. If one of the following properties is important to your application than FRP would be a good choice. If two or three properties are important to your application than FRP is an outstanding choice and should not be discounted unless you have strong, valid reasons for selecting an alternative material.

A list of beneficial properties of FRP:

-FRP requires virtually no maintenance such as cleaning or rust removal

-FRP is not electrically conductive

-FRP does not conduct heat well

-FRP is transparent to radio and electromagnetic signals

-FRP is lightweight and easy to install

-FRP will not rot or rust and is corrosion resistant

For more information on Redco FRP products, contact Redwood Plastics.

Need a Ramp? Try Mini-Mesh

One of the more common inquiries we receive is from customers looking for a surface for walkways or ramps. Fiberglass reinforced plastic (FRP) performs quite well in this application. All Redco FRP is anti-slip to some degree and many types have, or can have, a grit surface added. Probably the most popular ramp surface would be the grey Mini-Mesh. Mini-Mesh FRP sheet has smaller holes, only 3/4″ x 3/4″, which means that many small objects – such as keys – cannot fall through. The increased surface area also means wheels travel over it more easily. The grating is strong, will withstand the weather, and will not rot like wood nor corrode like metal. As you might expect, FRP is more expensive at first (upfront cost) but will have a lower life-cycle cost as it will last much longer and be virtually maintenance free.

Mini-Mesh is easily affixed to its application. It can either sit in a trough, as is common for marine applications, or it can be bolted into a substrate via M-clips. The picture below is for a wheelchair ramp that we actually supplied Mini-Mesh for. It is both attractive and well-suited to this application.

For more information on Mini-Mesh or other RedcoFRP products contact Redwood Plastics.

Case Study: Architectural Pyramids

The Vintage Club in Indian Hills, California had a problem. The club used architectural pyramids made of lumber to cover their air conditioning units. However, the harsh desert elements (and insects) took their toll on those pyramids resulting in maintenance costs of $75,000 ever other year. The club decided this was cost prohibitive and searched for a solution which led them to fiberglass reinforced plastic (FRP), more specifically EXTREN by Strongwell. FRP can be UV-coated to withstand the sun and is not susceptible to rot or insect attack. The pyramids look just as beautiful as before and no longer require the expensive and time-consuming maintenance as before. More than anything, FRP displayed its worth as a material that can solve multiple problems at once.

For more information or a quotation on FRP materials contact Redwood Plastics.

FRP Equals Fun?

Maybe that’s a stretch…Or maybe not? Redco™ Fiberglass reinforced plastic (“FRP”) is commonly seen as an “industrial” product but creative, even fun, applications for FRP are located all over the world. In fact, many of the properties that make FRP valuable to the world of heavy industry make it equally valuable in applications for the everyday public. Let’s take a look at a few examples:

Playgrounds:

FRP comes in a wide range of standard colors and is very durable. FRP grating makes an excellent anti-slip surface for children to play on. If the grating is suspended, dirt and debris will simply fall through the holes making the grating  virtually maintenance free. Colors can be mixed and matched to create a true “playground” feel. This picture is from Madison Square Park in New York.

virtually maintenance free. Colors can be mixed and matched to create a true “playground” feel. This picture is from Madison Square Park in New York.

Waterparks:

FRP grating does not corrode and resists chemicals such as chlorine. It is also available fully UV-protected by being painted by the manufacturer to withstand outdoor weathering. FRP is non-conductive and will outlast wood or metals in the same application. Also, FRP looks great and can fit virtually any theme. It absorbs no water and can handle submersion.

Others:

FRP is also widely used in marinas, even private docks. Mini-mesh is particularly popular as the small spaces between the squares of grating keep small items such as keys from falling through. It has been used to create attractive and safe ramps or decorative, insect-proof pyramids in in the Southwestern U.S. FRP is available in so many profiles, colors and resin systems that you have to ask yourself – why isn’t it seen as more “fun”?

For more information or for help with your FRP project – Contact Redwood Plastics