News

Pultrusions For The Pool

One application for Redco™ pultruded FRP is in custom swimming pools. If you’re a swimmer, you’ll recall how when you exit the pool there is grating which covers an overflow “trough”. Pultruded FRP (fiberglass reinforced plastic) is superior in this application because it will last longer than many “commodity” grade plastics. Furthermore, for outdoor pools FRP grating can be top-coated, or even fully painted, in UV-inhibiting paint. The key when designing your application is to know the limitations of the FRP. The sheets will be 48″ in length and can range in width from 12″-18″. It is those thicker bearing bars that must span the gap with the cross-rods holding the system together. The grating is available with medium or fine grit – though fine grit is usually preferred as it is easier on the swimmer’s feet. A 12″-18″ wide x 48″ length x 1″ thick I4000 panel will cost approximately $125-$180/each. USD depending on resin system and grating profile.

For more information contact Redwood Plastics.

Water and Wastewater

Water corrodes metal and rots wood: it is that simple. Fiberglass reinforced plastic (FRP) was meant for applications such as these and over a period of decades our product line has expanded to include several FRP products uniquely suited to water and wastewater applications where corrosion and rot would be of particular concern. These solutions include handrail and ladder systems, weirs, scum baffles, flight panels and fiberglass baffle panels. Redco EXTREN, SAFPLANK and custom pultrusions also are excellent in odor control cover applications. Surrounding these varied applications is FRP grating, either molded or pultruded, which provides a safe, long-lasting and maintenance-free alternative to metal walkways.

FRP is also very chemical resistant and can be produced with vinyl ester resin that is impervious to even saturated chemical environments. For potable water applications many FRP products can be produced NSF complaint. FRP’s numerous advantages and benefits in water/waste water applications should not be overlooked.

FRP Grating – Stocked Profiles

Redco FRP molded grating can be supplied in a number of profiles, from 8 feet in length all the way to 20′. However, we do not stock these profiles all at once.

Commonly we will stock grey and yellow with secondary grit surface grating in 4′ x 10′ and 4′ x 12′ profiles. A 1.5″ x 1.5″ square pattern is the most common but some branches will stock 1″ x 1″ square grating. Most branches also stock the mini-grid profile, which is only in grey in 4′ x 10′ and occasionally 4′ x 12′ sheets. The food-grade green with no grit is a special order as are 4′ x 8′ sheets of any profile. Our pultruded grating is not stocked and brought in custom. This connects to another issue; however, in many applications pultruded grating is superior. It is more expensive but it will perform better with less deflection while lasting longer. Combined with the ability to customize the pultruded profile, the product has clear advantages over traditional molded grating.

For more information on our RedcoFRP please contact us.

Phenolic Grating Handles The Heat

Traditionally, fiberglass reinforced plastic (FRP) materials are made with a vinyl ester or polyester resin. While the resins can have flame-retardant additives included in the resin, sometimes these properties still don’t meet the required standards. In these cases, and specific applications such as offshore oil & gas platforms, Redco Phenolic grating* may be the answer.

The phenolic grating is the first to receive U.S. Coast Guard approval for meeting the Policy File Memorandum 2-98 for fire retardant grating meeting structural fire integrity Level 2(L2). The grating will resist deformation and carry its design load in temperatures up to 1700 degrees Fahrenheit for one hour. But this resistance to extreme thermal conditions is just one of many advantages Redco phenolic grating offers:

- Strength – can take 2.4x the load of equivalent steel grating

- Lightweight – 1/3rd the weight of equivalent steel grating

- Ease-of-fabrication – does not require hot-work or heavy equipment to work with

- Corrosion resistance – offers the same anti-corrosion benefits as other FRP materials

- Memory – bounces back after impact, unlike metal grating

Not convinced yet? Click here to take a look at this eye-opening comparison of phenolic grating vs. aluminum

For inquiries on Redco phenolic grating or our other FRP products contact us today.

Case Study – Secondary Containment

One advantage of fiberglass reinforced plastic (FRP) is that it lets you be creative with applications. Such was the case with American Electric Power who required an oil containment system for their electrical substation equipment. Previously, concrete was used but was labor-intensive and difficult to install in remote areas and under certain environmental conditions. FRP turned out to be an excellent solution because it was light, took only half the time to install, and came in a kit form complete with required drill bits and hardware. Materials used were a mixture of Composolite and EXTREN 525 components. The customer was very pleased with the outcome and even suggested it could one day become the industry standard.

To see the full case study by Strongwell online click here.

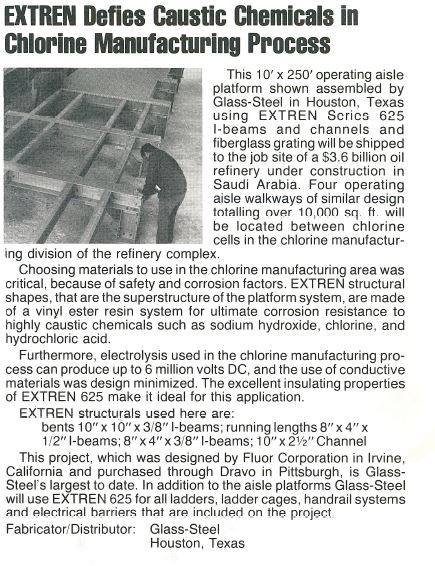

Classic Case Study – EXTREN 625

FRP (fiberglass reinforced plastic) products may seem like a new product – but they’re not. In fact, Redco FRP’s manufacturer, Strongwell, has been in business since the 1950’s! For many decades now FRP has shown its versatility, strength and longevity in countless applications. Recently Strongwell’s Marketing Department posted a case study from 1993 in which EXTREN series 625 (polyester resin, fire-retardant) grade FRP was used in the chlorine manufacturing division between the cells. However, FRP with the more corrosion resistant vinyl-ester resin was selected for the chlorine manufacturing area itself. In addition to the corrosion-resistance, there was a potential electrical hazard meaning the use of conductive materials had to be minimized. FRP is non-conductive and this provided an added safety benefit in the application.

You can read the original article in its entirety below:

FRP Ladders – Is the Switch Worth It?

Fiberglass reinforced plastic (“FRP”) ladder and cage systems were one of the first pultruded products on the market and have a proven track record of success since the 1950’s. The FRP ladders do cost more but what is the lifecycle cost in comparison to metal ladder systems? Let’s compare the relative advantages of each:

Metal:

-Readily available from distributors and contractors

-Proven product

-Well-known…The “standard”

-Less expensive than FRP

Fiberglass reinforced plastic:

-Available in custom sizes and configurations

-Will not rot

-Will not rust

-Non-conductive

-Corrosion-resistant

-Virtually maintenance free

-Meets any North American safety standard

The fact is in any environment where corrosion OR rust OR electrical hazards OR maintenance concerns may be a factor, FRP ladder systems are a safer choice. Their ability to resist both natural and artificial elements mean they last much longer and will survive long after a metal ladder system needs replacement. All we need is measurements or a drawing to quote a ladder system…The process is easier than you might think as many of the components and specifications are standard. The ladders come standard in OSHA safety yellow and there are a few options we can help you select. But know that the switch is worth it.

For more information contact Redwood Plastics.

Phenolic Grating Handles The Heat

FRP materials have countless applications in the oil and gas industry, everything from handrails and grating to entire custom platforms. Several of the properties of FRP make it an ideal building material. Consider an offshore platform: FRP will not rust or corrode due to moisture or salt air and is resistant to a wide variety of chemicals.

But oil and gas could also mean hazards from flame and heat during a disaster and Redco™ DURAGRID® Phenolic Grating is an excellent choice in areas where this may be a hazard. The grating had excellent flame retardancy, low smoke toxicity and will keep its structural integrity better than other composite options. Redco DURAGRID® Phenolic Grating is the first composite grating to receive U.S. Coast Guard Approval. The grating also complies with Annex 1, Part 2, 2.6.1 and 2.6.2 (smoke and toxicity testing) FTP Code (International Code for Application of Fire Test Procedures) issued by the International Maritime Organization. Furthermore, DURAGRID® Phenolic is accepted for use in locations and applications allowed in the U.S. Coast Guard Policy File Memorandum 2.98 for fire retardant FRP grating meeting structural fire integrity Level 2 (L2).

This is yet another example of fiberglass composites filling a niche requirement in the oil and gas industry and an option that should be strongly considered.

For more information contact Redwood Plastics.

Quoting FRP

If there is any single area of confusion for Redco FRP customers it may be the quotation process on fabricated work. The process can take up to a week and customers are often caught off guard by the number of questions they are asked. You will note on a previous article we mentioned that engineers are personally (legally) responsible for their designs. This means that the engineer who reviews your drawings and specifies any variables into the project must ask the pertinent engineering questions in order to practice due diligence and protect themselves from legal liability.

In practice the procedure and timeline to quote a fabricated job is as follows:

1.) We discuss the application with you and get any drawings and specifications you may have (1-2 days)

2.) The information is submitted to our manufacturer

3.) Manufacturer reviews the information and either comes back with a budget quotation or provides a list of questions that need to be answered before the quote can proceed (1 week)

4.) Upon answering of the final questions and approval of the budget price, manufacturer engineers will either make, or request a set of, technical drawings to be signed by the customer approving a final price and the complete order (1-2 weeks)

5.) The order is pultruded and fabricated (5-7 weeks)

6.) Order is shipped to the local Redwood Plastics branch and is then ready to be shipped on site (1 week)

Note the time frame it takes to quote and fabricate the job. We supply that information to save you disappointment and a frequently asked question we get is “can you speed the lead time up?” because we’re very busy and everyone is asking for faster production – it’s simply the length of the work queue. Please note these lead times do not apply to stocked FRP material such as standard sized grating and EXTREN sheet which, if in stock, can be shipped out from us or the manufacturer within 1-2 days.

For your questions on FRP projects or materials please contact us.

What’s In A Stamp?

Engineering is a line of work with plenty of prestige. In general, engineers are put through rigorous education and schooling and are paid well for their services. However, some people do not know that engineers are personally, legally, responsible for the designs they make. Therefore when working on a design using Redco FRP materials it is an absolute must that we have all available information on hand. Information including the operating environment of the FRP, spans, loads and safety factors.

Neither us, nor our manufacturer Strongwell, will quote unless we have the information we need! Drawings for the finished project in the U.S. are required to be stamped by an engineer who has been certified by whichever state the project is destined for. Fortunately, Strongwell has engineers for many U.S. states on staff. If a stamp is required for a state we don’t have an engineer for, representatives are kept on retainer who can provide the stamp. Rest assured when you contact us for your project – anywhere in North America – we can provide the stamp you need.