News

Reinforce With GRIDFORM and SAFSTRIP

The sight of rebar reinforcing concrete is a staple of the construction site. Steel rebar provides support to the concrete form greatly increasing its strength. Fiberglass reinforced plastic as a structural material is starting to become more known; however, knowledge of FRP’s ability to reinforce other construction materials is lagging. However, two Redco™ products provide just such strength equaling or surpassing traditional alternatives.

GRIDFORM™ is a prefabricated reinforcement specially built for bridge decks. It consists of a double-layer of I-bars and reinforcing cross-rods. These are then bonded to a 1/8″ thick FRP plate. Redco™ GRIDFORM™ is light with panels that weigh only 4.7lbs/ft.sq and can be pultruded in very large segments. Concrete can then be poured over the GRIDFORM™. The benefit of an FRP bridge deck system is that our material does not corrode, like metals, and the expected lifespan of the bridge is increased many times over a steel-reinforced system.

It does not take long to find examples of bridges that are being used well beyond their expected lifespan. The cost of building a modern bridge is large and replacement is often slow if not outright prohibitive due to costs. Redco™ GRIDFORM™ aids in increasing the service life of a bridge: which just makes sense given the many bridges that need replacement – using FRP will reduce the financial burden on governments in the future.

It does not take long to find examples of bridges that are being used well beyond their expected lifespan. The cost of building a modern bridge is large and replacement is often slow if not outright prohibitive due to costs. Redco™ GRIDFORM™ aids in increasing the service life of a bridge: which just makes sense given the many bridges that need replacement – using FRP will reduce the financial burden on governments in the future.

But what if you have an older bridge already built?

Redco™ SAFSTRIP™ may be the answer. SAFSTRIP™ is a glass fiber reinforced strengthening strip that can be attached to existing concrete without much preparation or skilled labor. The material uses a premium vinyl ester resin. With its high bearing and longitudinal properties SAFSTRIP™ strengthens the flexural properties of concrete. There are other advantages to SAFSTRIP™ in that the structure is immediately usable and secure right after the product is installed.

So – what do you think about FRP reinforcement now?

Contact us:

E-MAIL: sales@redwoodplastics.com

CDN/USA: 1 604 607-6015

Safety Solution – DURATREAD™

Even those that know what fiberglass reinforced polymer (FRP) is have stereotypes of the material. Products such as molded and pultruded grating, or the Redco™ EXTREN® line of structural shapes is what comes to mind.

How about stair treads?

Redco™ Duratread™ is a molded FRP safety solution designed to keep stairways safe. The treads are designed to be installed over traditional stair materials such as concrete, metal and wood in environments where they would be in contact with slippery substances. Duratread™ is available in thicknesses of 1/8″ and 1/4″. Standard depths are 8″, 9″, 10″, 11″ and 12″. All stair tread covers are available in 12′ lengths. Other lengths and depths are available upon request.

The treads come standard as a dark grey with a safety yellow nosing. They consist of a molded fiberglass mat available with multiple types of resin. The coverings are then coated with an aluminum oxide grit. It is important to note the coverings are ADA compliant, durable and virtually maintenance-free. When you factor in the possibility of injured employees and the requisite consequences due to something as simple (and preventable) as a slippery step – the Redco™ Duratread™ just makes sense as a cost-effective preventative safety measure.

The treads come standard as a dark grey with a safety yellow nosing. They consist of a molded fiberglass mat available with multiple types of resin. The coverings are then coated with an aluminum oxide grit. It is important to note the coverings are ADA compliant, durable and virtually maintenance-free. When you factor in the possibility of injured employees and the requisite consequences due to something as simple (and preventable) as a slippery step – the Redco™ Duratread™ just makes sense as a cost-effective preventative safety measure.

Duratread™ is recommended for:

• Amusement/Water Parks

• Hotels/Motels

• Outdoor Stairways

• Outdoor Sports Facilities

• Restaurants

• Food Processing Facilities

• Chemical Processing Plants

• Water/Wastewater Treatment Facilities

For any questions on this or our other FRP materials please contact us:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

The Nuts and Bolts of FRP

Fiberglass Reinforced Polymer (FRP) is known for a number of valuable advantages first and foremost being corrosion-resistance. The EXTREN® line has many structural components that are equivalent alternatives to similar wooden and steel shapes. However, we are sometimes asked about applications in extremely corrosive environments and environments that cannot have any metal. How can you secure the structure if you cannot use metal bolts?

steel shapes. However, we are sometimes asked about applications in extremely corrosive environments and environments that cannot have any metal. How can you secure the structure if you cannot use metal bolts?

The answer is the Redco™ Fiberbolt® – a nut and bolt system for applications with the above requirements. Fiberbolt® is a pultruded stud with threads cut in a glass mat reinforced outer layer. The bolts are strong, low maintenance and transparent to electromagnetic waves (though they do not possess the thread shear strength of steel). They are available in standard diameters from 3/8″-1″ with lengths up to 4′ available on request.

As an added benefit Redco™ Fiberbolt® looks very similar to metal bolts and will not appear out of place. The bolts can bring significant benefits to the following applications:

- Chemical Process Equipment

- Air and Water Pollution Equipment

- Marine Applications

- Low in Conductivity

- Cellular Antenna Mounts and Screens

- Computer Testing Facilities

For answers to your questions on Fiberbolt® or our other FRP materials please contact us:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

The Basics of FRP

There are many reasons to choose fiberglass reinforced polymer (FRP) for your application and we do our best to explain the advantages of the material any time we can. However, once in awhile, it’s good to take a step back – learn the basics and see the strength of FRP literally from the” inside out.”

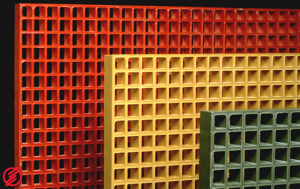

If people encounter FRP it’s most likely as molded grating. The kind of square, gritted grating that is usually yellow or grey in color. The reason it is so common is that it is relatively easy to make. A resin is mixed with a curative and poured into an open mold. Heat is added, which acts like a catalyst solidifying the resin. Inside the resin are glass rovings, which provides the strength that FRP is known for.

However, most of our products are pultruded and are formed in a different method involving layering of several materials. Glass rovings are pulled by a machine that covers the rovings with a glass mat. The rovings provide great strength lengthwise while the glass mat provides reinforcement in all directions. These glass materials are then bound on top by a synthetic surfacing veil that keeps the glass components in the core of the material and also provides UV protection. It is the resin that binds the material together, protects the glass fibers and the corrosion-resistance FRP is known for.

Multiple resins and grades are available for FRP products but polyester and vinyl ester are the most common. Polyester is the more economical option and offers good corrosion-resistance. Vinyl ester is designed for extremely corrosive environments and is considered a premium resin. Both offer similar strength, both can be made in fire-retardant grades and both share similar properties such as electrical non-conductivity. FRP materials do not rot, rust, mold and many installations are still in use decades later without requiring time-consuming maintenance or replacement.

In case it is of interest a short video on the pultrusion process is below. Please contact us at sales@redwoodplastics.com if you have questions or require assistance with our FRP products.

3 Advantages to An Outstanding Application

Fiberglass Reinforced Polymer (FRP) products offer significant advantages over traditional building materials in many applications and the benefit of a lower life cycle cost. That said, people tend to look first at the “price tag” vs. traditional materials and can become uneasy comparing the price of FRP. The easiest way to decide whether or not the materials suit your application is counting the advantages they offer in your application. If FRP offers one advantage then it is a “good” choice and should be considered. Two advantages means FRP should be considered an “excellent” choice and at three or more advantages FRP is an “outstanding” choice in comparison to traditional building materials.

Fiberglass Reinforced Polymer (FRP) products offer significant advantages over traditional building materials in many applications and the benefit of a lower life cycle cost. That said, people tend to look first at the “price tag” vs. traditional materials and can become uneasy comparing the price of FRP. The easiest way to decide whether or not the materials suit your application is counting the advantages they offer in your application. If FRP offers one advantage then it is a “good” choice and should be considered. Two advantages means FRP should be considered an “excellent” choice and at three or more advantages FRP is an “outstanding” choice in comparison to traditional building materials.

What are those advantages?

The following list should help you decide:

Corrosion Resistance: The most well-known advantage of FRP, high levels of corrosion resistance means the material vastly outperforms steel and wood in many applications providing multiple benefits including reduced maintenance and increased safety. Please note corrosion resistance is standard in all resins.

Electromagnetic Transparency: In applications where radio waves or other radiation needs to pass through material, metals are not an option. Wood is a choice, but it is a high-maintenance option that will eventually need to be replaced and FRP (which can be worked similarly to wood) will greatly outlast wood.

Maintenance-Free: FRP materials do not require the maintenance, such as repainting or cleaning, of traditional materials. The synthetic surfacing veil provides UV protection for our products but at worst, after many years, they may slightly discolor without any effect to the structural properties of the material. This is especially useful in difficult locations where maintenance is costly or other prohibitive.

Lightweight: Much lighter than all traditional building materials, FRP can be installed quicker and more easily than other materials.

Electrical Non-Conductivity: FRP materials, unlike metals, do not conduct electricity and this can provide required safety benefits in certain applications.

Low Thermal Conductivity: Unlike metals which, in the case of disaster such as a fire, spread heat readily, FRP materials conduct heat poorly and would provide additional safety and ease of escape for workers in the event of a fire.

Fire Retardancy: FRP materials of both the polyester and vinyl ester resin types can be made fire retardant.

Ease of Fabrication: FRP is easy to work with common tools, similarly to wood.

If three or more of the advantages above are relevant to your application then Redco™ FRP is indeed an outstanding choice for your application.

For answers to your questions on FRP materials please contact us.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

To Grit or no Grit?

The three questions we are most often asked when a customer is considering part of our line of fiberglass reinforced polymer (FRP) are…

1.) “I need it corrosion resistant” (answer: all of our resins have at least ‘good’ corrosion-resistance)

2.) “I need a UV inhibitor” (answer: all of our resins use a UV inhibitor system)

3.) “I need an anti-slip surface” – this is a little complicated…

Similar to the other answers above, the short answer would be all of our grating is anti-slip. But the grating systems differ whether or not it is pultruded or molded. The pultruded system is easiest to answer. Ordering without a grit system is possible, on request, but most stocked material will have grit embedded in the surface.

Similar to the other answers above, the short answer would be all of our grating is anti-slip. But the grating systems differ whether or not it is pultruded or molded. The pultruded system is easiest to answer. Ordering without a grit system is possible, on request, but most stocked material will have grit embedded in the surface.

Molded grating is a little more complicated. The molding system involves glass rovings and resin layered in an open-faced mold. When the grating is cured a miniscus forms at the top of the grating’s surface. This concave surface forms naturally and provides a measure of anti-skid protection. If grit is desired, there are two types of grit that can be applied:

Secondary grit (“Add-on”): this gritting system involves an epoxy being added on to the surface of the grating and coarse quartz added on the surface followed by a top-coating of pigmented sealing epoxy added to seal the grit. This has the benefit of economy and can be applied on any standard sizes of grating kept in inventory.

Integral grit: A more complex system, this premium grit must be spec’d in along with the initial material order – it cannot be added after the grating cures and therefore cannot be added on to materials kept in inventory. The benefit is the grit is part of the structure of the grating, it is less likely to chip and more likely to retain the optimal non-slip surface. This system will require a longer lead time than secondary gritting.

If you have other questions on gritting, grating, or our other FRP products, please contact us.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

7 Steps To Your SAFRAIL Ladder

One thing many people do not realize is how often they come in contact with Fiberglass Reinforced Polymer (FRP) at work. One of our more established products is Redco™ SAFRAIL™ in use since the 1950’s. The requirement for a corrosion-resistant, yet safe and strong, ladder solution have existed as long as the industrial plants that require them have. By their very nature the ladders and cages in these facilities exist to provide workers with safe transportation around the facility. Corrosion of those ladders or cages could potentially lead to a catastrophic event…And expensive punative consequences for your company.

work. One of our more established products is Redco™ SAFRAIL™ in use since the 1950’s. The requirement for a corrosion-resistant, yet safe and strong, ladder solution have existed as long as the industrial plants that require them have. By their very nature the ladders and cages in these facilities exist to provide workers with safe transportation around the facility. Corrosion of those ladders or cages could potentially lead to a catastrophic event…And expensive punative consequences for your company.

The good news is there is a solution and one that has stood the test of time. FRP materials have 80% the strength of steel, easily enough to support men on a ladder or provide the safety required of a cage. Redco™ SAFRAIL™ comes from the world’s leading manufacturer of pultruded products ensuring the consistent quality you need to have peace of mind that your valued workers are safe. Fiberglass outlasts aluminum and steel with virtually no maintenance. A further advantage is even the standard grade material is a high-visibility, fire-resistant, UV stabilized polyester resin.

7 Steps To Your SAFRAIL FRP Ladder:

1.) Know the length of the ladder you require

2.) Determine if you require a cage, if so what is the starting height and exit method? We can assist if necessary.

3.) Select a resin. The base resin is a fire-resistant polyester; however, a premium vinyl ester system for extremely corrosive environments is available.

4.) Select a color. The standard color is a safety yellow but custom colors may be made available upon request.

5.) Painting with polyurethane paint is recommended to prevent UV fading of the color. lack of painting will not affect the structural integrity of the ladder system.

6.) Select one of the 4 ladder systems available for selection on our brochure here.

7.) If none of the standard ladder types are acceptable, and you have drawings and specs, we can help design a custom solution.

To inquire about a SAFRAIL ladder system or other FRP solutions please contact us today:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

Coastal Solutions

Redco™ FRP materials are designed for harsh environments, where traditional materials such as steel and wood may suffer corrosive degradation. When you think of “corrosive environment” some sort of exotic locale such as giant waste treatment plant or oil rig may come first to mind – but an idyllic oceanfront environment probably would not!

However, the constant salt breeze with the resulting moisture in the air creates one of the most corrosive environments  you will encounter in everyday life. The assault on structures is constant and fortunately we can offer a variety of solutions.

you will encounter in everyday life. The assault on structures is constant and fortunately we can offer a variety of solutions.

Architectural:

Imagine bright, attractive fencing or railing that does not rust, corrode or need repainting every year. One stereotype of FRP materials is that they are strictly for “industrial” uses and are not attractive. However, Redco™ FRP materials are not only very attractive, comparable to the best steel or aluminum structures, but they require almost no maintenance and offer significant benefits and a lower life-cycle cost.

Piers/boardwalks:

A pier or boardwalk not requiring tar-soaked wood seeping its hydrocarbons into the ocean is a reality. FRP materials offer the strength to build even a larger pier, yet will not corrode in a harsh coastal environment. On the contrary, it could be argued the material is more attractive and does not have the unpleasant smell of the oil-based preservatives used to make wood suitable for coastal use.

For answers to your questions on FRP materials please contact us.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

Waterpark Solutions

Taking one’s children to the local water park is a fun activity for many families. Water

Taking one’s children to the local water park is a fun activity for many families. Water Parks provide a fun way to cool down in the summer’s heat. But have you ever looked closely at the structures in the park? Many parks have metal structures and the constant exposure to water and chemicals such as chlorine have a major corrosive effect on the facilities. The sight of rust slowly oozing from corroded structures is not only unpleasant but in certain situations such as parks that do not use chlorinated water, serious health issues such as tetanus infection may be a potential issue. While the possibility of harm might be rare – if such an issue is preventable, why would you not want to prevent it?

Parks provide a fun way to cool down in the summer’s heat. But have you ever looked closely at the structures in the park? Many parks have metal structures and the constant exposure to water and chemicals such as chlorine have a major corrosive effect on the facilities. The sight of rust slowly oozing from corroded structures is not only unpleasant but in certain situations such as parks that do not use chlorinated water, serious health issues such as tetanus infection may be a potential issue. While the possibility of harm might be rare – if such an issue is preventable, why would you not want to prevent it?

Fiberglass Reinforced Plastic (FRP) materials, such as Redco™ EXTREN®, are corrosion-resistant to both water and chemicals. They are strong, lightweight and easy to build with. In fact, fiberglass materials can be affixed with fiberglass bolts to ensure long-lasting strength of the entire structure. Depending on the grade, the EXTREN® line comes in three colors – olive green, slate grey or beige – but custom colors are available apon request. FRP materials will not rot or rust and are electrically non-conductive. They make an ideal building material for water park applications.

For more information on our waterpark solutions click here or contact us today:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

When is Fiberglass the Better Choice?

Trying to decide what materials to use for a new structural development project? There are a number of materials to consider when engineering and designing a new structure, and Fiberglass Reinforced Polymers could be the right choice. These materials have outstanding properties that are better suited for a variety of environments.

FRP, or Fiberglass Reinforced Polymers, certainly aren’t new to the marketplace. FRP’s have been around for many years, but it has taken some time for them to become universally accepted around the world, by Engineers, architects, and developers. FRP’s, for commercial use, have been extensively researched since the 1930’s, however, Engineers, architects, and developers, being unfamiliar with the material and uncertain as to which grade of FRP is the correct one, sometimes overlook FRP as a structural material.

Understanding FRP plastics and where they are best suited is important, and comes from an understanding of the products strengths and weaknesses. There are many grades of FRP’s and not all of them can be used for the same application. Although all fiberglass products are not created equal, FRP products generally share these characteristics:

- Lightweight – Weighs 80% less than Steel

- Corrosion Resistant

- Low Conductivity – Thermally & Electrically

- Nonmagnetic – Electromagnetic Transparency

- High Strength

- Dimensional Stable

- Low Maintenance

The end result: Fiberglass Reinforced Polymers becomes an excellent substitution for steel, aluminum, concrete or wood. In cases where the use of traditional products comes into question, such as situations where there may be rotting or corrosion, FRP products are often a much more sound choice. These FRP products typically last longer, are easier to maintain, and improve safety.

Significant cost savings are also a key benefactor when choosing FRP products. Not only because they have significant longevity and are virtually maintenance free, but also because the materials are lighter. The reduced weight decreases shipping costs and makes installation easier, which saves time during the construction phase. As an example, in a wastewater treatment facility, FRP was used as an alternative to galvanized steel for handrails, ladders, and walkways; the installation was 50% faster due to the lightweight materials and ease of assembly.

Although they have many uses and applications, REDCO™ Fiberglass Reinforced Polymer products are typically available in three major product types; structural shapes, grating, and wall paneling.

Structural Shapes

Structural Shapes

Structural shapes (REDCO™ EXTREN®) are produced in hundreds of shapes and are a strong, lightweight option for platforms, walkways, structures, floors, ladders, panels, decking, enclosures, handrails, and covers.

Grating

Grating

Grating is available in both molded (REDCO™ DURAGRATE) and pultruded form (REDCO™ DURADEK® & REDCO™ DURAGRID®), and is best suited for higher traffic applications, like walkways, docks, drainage grates, and platforms.

Wall Panels

FRP wall panels are suitable for less demanding applications, like commercial kitchens and washrooms but can also be used for impact resistance applications, such as storm panels and ballistics resistance panels.

Applications have been provided to a variety of industries including:

- Architectural

- Tool Manufacturing

- Dairy and Food Processing

- Oil & Gas

- Water/Wastewater Treatment

- Electrical Substations

- Waterparks

- Marine & Fisheries

- Chemical Processing

- Hotels & Restaurants

- Power Plants

- Pulp and Paper

- Material Handling

- Hospitals

When choosing the correct grade of fiberglass, there are some factors to consider and understand. These factors include chemicals that may be present in the environment and load bearing capacity. Fire resistance concerns must also be evaluated, as not all grades have the same level of fire retardant additives.

Load bearing charts, tolerances, and properties tables are available from Redwood Plastics, and can help you make the best decision when choosing FRP products. Knowing exactly how each grade of FRP withstands use, and how they are made, is key. Also ensure that you are referencing the same brand in the charts that you are using in the application, as the properties will differ from one supplier to the next.

In Conclusion

Fiberglass Reinforced Polymer products are often the best choice, and should not be overlooked as a material to construct with, especially in structural, architectural, and design projects. REDCO™ FRP’s are a great solution when other materials are either ill-suited mechanically or economically. There are a few factors to consider when selecting, ordering, and installing FRP products, but Redwood Plastics has experience and knowledge to help for any given application. Contact us today.