News

Pultruding On Budget

Over the course of a few articles on this website, the differences between Redco™ pultruded and molded grating has been discussed. Molded grating is traditionally the more economic of the two and is easier to install. However, pultruded grating has properties that match or, in most cases, exceed molded grating on most dimensions. Usually, the only “drawback” with pultruded grating is the upfront cost. The grating will perform better and will be well-worth the investment but sometimes that upfront cost is a tough sell.

There are; however, two exceptions. The Redco™ line of pultruded grating has two options that have less upfront cost with the same excellent properties of the other configurations. They were designed and mass-pultruded with economy in mind for cases where specific profiles were not specified and budget was a key issue.

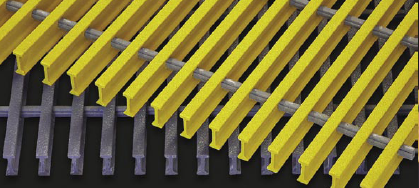

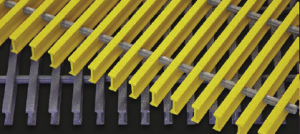

“T-3300 Economy” is a thin grating with “T” shaped bearing bars and 33% space in between the bars. This configuration is suitable for foot traffic. The “I-6500” line is a regular duty pultruded profile that is also suitable for foot traffic but not as thin as the T-3300 line and, as the name suggests, is in the “I” profile. Both are available in standard 3, 4, and 5 foot widths and standard 8,10,12, and 20 foot lengths.

For your inquiries on Redco FRP products:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

Veils, Paints and UV-Inhibitors

Representatives that help distribute Redco™ products take an online test at regular intervals designed to ensure that the rep’s product knowledge is maintained at a high-level. Recently, the reps were faced with a simple question and we wanted to see how they would respond: “Are Redco™ FRP products UV-Stabilized? Yes or no?”

Don’t get us wrong – our reps know whether or not our products are stabilized! But the trick of the question was the “yes or no” responses that were permitted. It was designed to see how the rep would tackle a question that is not simply “yes” or “no”. The reality is that Redco™ FRP is UV-stabilized as far as strength, the material’s physical properties will not erode due to UV exposure and this is because of the synthetic surfacing veil which is applied to the material as part of the pultrusion process.

But the products do not come UV-stabilized for color unless requested. It is important for our representatives to ask if this is important, in order to not disappoint our customers. However, it is helpful as well if our customers say that UV-stabilization for color is important up front. If you have purchased a product without UV-stabilization (for color), the product can be protected by the simple application of polyurethane paint. More information can be found on a blog here.

The issue of the UV-stabilization of Redco™ FRP is not cut and dry and is something that should be part of the sales process. For more information on Redco products contact us today:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

How Strong? Try Military Strong

FRP (fiberglass reinforced plastic) has many applications across a number of industries. The ones that come to mind easily would be waste water or waste treatment, oil and gas and other utilities such as electricity distribution. One concern of customers who have not worked with FRP before is strength – how strong is it?

Try modern armor.

That’s right – it isn’t well known that FRP is strong enough to be used as armor and has been for several years, even being used in the war in Iraq. How does it work? Specialized glass reinforcement is added to a proprietary resin formula in a matrix. When hit with a projectile the panels absorb the energy as they delaminate. In that way it is known as a composite armor.

There are criterias for ballistics penetration set out by a couple of agencies including the Nation Institute of Justice (NIJ). Those familiar with this testing might say “Well, I bet Redco FRP can only meet the level 1 ballistic criteria?” which is the lowest on the scale. Not true – the panels can be produced to level 3A (or simply 3, depending on the scale) and can withstand the impact of a .44 magnum round. Don’t believe it? Click here for video.

The applications for this are not as limited as you might think. For example, so-called “panic rooms” have become more popular in recent years and FRP composite armor would be ideally suited to this application. The material could also provide protection from courtrooms, to banks, to convieniance stores – essentially anywhere that might be threatened by firearms. In addition, the material is easy to work with. Ordinary carpentry tools would work but carbide tipped blades and drill bits are strongly recommended due to the abrasion the glass reinforcement applies to the tools.

For inquiries on other strong Redco FRP products contact us:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

NSF 61?

For those that do not know, NSF International is a global independant public health organization that provides standards for testing, materials and education used in most places the word “sanitation” may apply. In fact, NSF stands for the “National Sanitation Foundation” and was founded in the State of Michigan in 1944 – where NSF retains its headquarters to this day. At present, the NSF has a staff of over 1,200 and serves organizations in over 150 countries. “NSF 61” is actually shorthand for “NSF/ANSI Standard 61” and any materials that are distributed in North America for applications involving potable water must meet the standard. It is a comprehensive standard that addresses everything from pipes and faucets, to ladders, to filter mediums. For more information on NSF/ANSI Standard 61 click here.

What does this have to do with fiberglass reinforced plastic?

One of the largest industries for FRP systems is water treatment. We are almost always asked, “does your FRP conform to NSF 61?” the answer is “yes!” It is still an important to confirm with your rep that the proper components are specified to maintain NSF 61 compliance – but the point is compliance to NSF 61 is not a problem. For questions on our FRP products please contact us:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

FRP & The Environment

Plastics often suffer from a poor public image. Combining the words “plastic” and “the environment” in the same sentence seems to bring many people to imagine landfills clogged with plastic bags floating in the wind or plastic cups and bottles on laying on the side of the road. Regrettably, those images are often applied to the industry as a whole – unfortunate because the reality of industrial plastics is different.

The manufacturer of Redco™ FRP, Strongwell, has a defined environmental policy available publically here. All manufacturing locations have been certified to ISO 14001 standards. Numerous environmental initiatives have been implemented at the plant including:

-A reuse and recycle program on cleaning solvent that saves 25,000 gallons annually.

FRP – a sustainable solution

-Replacement of regular light bulbs with high-effeciency options

-Scrap reuse and donation program that has reduced the amount of landfall use annually by 700,000 lbs

-Enclosed production machines to reduce styrene emissions by 80%

Furthermore, Strongwell continues to fund third-party studies into “Life Cycle Analysis” studies, which are peer-reviewed, and consistantly show the environmental advantage of fiberglass reinforced plastic over traditional materials.

You might ask how a plastic reinforced material might be more environmentally friendly than those traditional materials?

What is important is the actual manufacturing of Redco™ FRP. Producing FRP requires less energy and emits less greenhouse gas than the production of traditional materials such as steel. While those materials may be recyclable, the recycling process does take energy and suffers from the carbon emissions required to transport those materials to a recycling facility. Meanwhile, due to Redco™ FRP’s longetivity and strength it will outlast traditional materials – and save the energy, time and chemicals that may be required for constant maintenance.

FRP, a sustainable material with an ever-reducing environmental footprint?

Yes.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

UTILICOVER® Fiberglass Trench Cover System

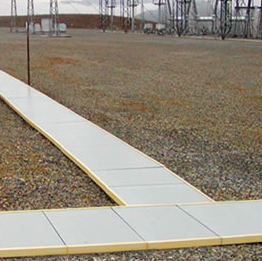

In recent years fiberglass reinforced plastic (FRP) has become a better known product. However, many customers are surprised to learn of the breadth of FRP applications. If you don’t know about a solution – there is no way it can help you. Redco™ UTILICOVER® is one FRP product that is not well known.

Like traditional covers made of metal, UTILICOVER® is strong and cost-effective. Unlike metal, it will not rust or corrode and is very light. Easy enough to be installed or removed by one person. Redco™ UTILICOVER® are basically maintenance-free, save the occasional light cleaning of dirt or debris that might find its way on top of the cover. FRP utility covers reduced weight means they save on replacement or installation costs that plague concrete covers. In fact, you could install by hand Redco™ UTILICOVER® more quickly than you could remove concrete covers using an excavator.

Like traditional covers made of metal, UTILICOVER® is strong and cost-effective. Unlike metal, it will not rust or corrode and is very light. Easy enough to be installed or removed by one person. Redco™ UTILICOVER® are basically maintenance-free, save the occasional light cleaning of dirt or debris that might find its way on top of the cover. FRP utility covers reduced weight means they save on replacement or installation costs that plague concrete covers. In fact, you could install by hand Redco™ UTILICOVER® more quickly than you could remove concrete covers using an excavator.

A utility cover should be the least of your worries. So don’t let them monopolize your time and manpower – choose Redco™ UTILICOVER®.

For additional assistance or questions on other FRP products please contact us:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

Double-Lock Stability

Need another reason why pultruded fiberglass grating outperforms molded grating?

Pultruded grating is our premium grating system and consists of two components: the large bearing bars and the cross-rods. Bearing bars are extremely strong components in latitudinal strength that come in “I”, “T” and rectangular profiles; however, it is the cross-rods that literally bind the system together. Cross-rods are pultruded specifically for a certain orientation of grating profiles and then machined in order to match a system of groves to the bearing bars.

Cross-rods come in three pieces – upper and lower spacer bars that lock in with the bearing bars and an epoxy coated wedge that is pushed through the center. In this way the system becomes locked both with an adhesive bond and a mechanical lock. This provides the grating with excellent dimension stability. Check out this brief animation:

For questions on our FRP products please contact us:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

Example Ellen

“Lifecycle cost vs. Upfront cost” – it is a constant process for us to explain the cost-savings of Redco™ FRP products when seen over time. Traditional materials are often cheaper; however, after maintenance and replacement costs are factored in FRP comes out as the more cost-effective material over time. While we can explain the reasons FRP has a lower lifecycle cost, including that it is virtually no maintenance and will not rot or rust, one notable case study can illustrate Redco™ FRP’s potential.

In 1979 DURADEK® grating was installed on Shell’s offshore Ellen platform in Southern California. After 34 years of continual exposure to the elements including sunlight, salt, rain, abuse from surface safety valves and even accidental sandblasting – not to mention 34 years of regular work – the grating is still in excellent shape. It has not needed any significant maintenance, repainting or replacement despite the harsh, corrosive environment it is subjected to.

For questions on our FRP products please contact us:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

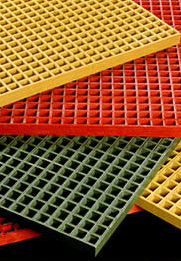

Grating – Why Choose Molded?

Redco FRP comes two broad categories of grating which we touched on in an older post “Molded or Pultruded Grating?” but a further discussion is required on the advantages of molded grating as there are situations where molded grating might be the better choice.

Advantages of Molded FRP Grating:

–Easier to install as there are no bearing bars to be concerned about. In pultruded grating, the bearing bars must carry the load and be orientated appropriately.

–Fabrication on-site is easier.

–Higher resin content (65%) than pultruded grating.

–Simple design

–Cheaper than pultruded grating

–Plentifully stocked at our manufacturer in a variety of profiles.

One factor in the economy of molded grating is the natural, anti-slip concave surface former during the manufacturing process. Added grit systems are available.

Molded grating makes sense under certain applications and may be the only choice for certain budgets. That said, pultruded grating is a superior form of FRP grating and should be specified whenever possible. Pultruded grating will last longer and suffer less deflection. Click here for our REDCO™ DURAGRATE® brochure.

For additional assistance or questions on other FRP products please contact us:

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684

Design and Support

Redco™ FRP products offer significant advantages over traditional materials in a variety of applications, many of which we try to draw attention to on this website. However, Redco™ FRP is backed by the Strongwell design manual – a powerful tool that is the industry standard and another reason to work with Redco™.

The design manual is an online guide that assists engineers in designing with Redco™ FRP. It includes over 400 pages of material. The manual gives in-depth information on the different products and important design factors such as load tables, deflection, shear strength, properties and tolerance. In addition, there are sections discussing corrosion resistance and fabrication techniques.

Along with the manual itself we can supply:![]()

- MSDS

- CAD Blocks

- Corrosion Resistance Guide

- Fabrication Worksheets

This combination of concise, reputable information allows us to bring our end-users excellent support in their individual applications. If you do not have engineers available to assist with your application, we have in-house engineers able to assist with your Redco™ FRP design. Fiberglass reinforced plastics are a valuable material, but like any structural system, must be designed properly – and we provide that assistance. It is critical to note that the design manual cannot be used for other non-Strongwell products. The properties of FRP vary based on the manufacturer and using the information to design with other materials is unsafe.

To request the Strongwell Design Manual please contact us at sales@redwoodplastics.com. Both Redwood and Strongwell reserve the right to refuse access to the manual so please provide us with as many details as possible on the scope, project and types of material being considered.

E-MAIL: sales@redwoodplastics.com

CDN: 1 800 667 0999

USA: 1 866 733 2684